How Artificial Intelligence Can Optimize Supply Chain Management

AI is Revolutionizing Supply Chain Introduction

Remember when “supply chain” was something only logistics managers talked about? Yeah, then 2020 happened, and suddenly we all became painfully aware of what happens when it breaks down. (No toilet paper, no GPUs, no semiconductors, the horror.)

Fast-forward to 2025, and one thing is crystal clear: the old way of managing supply chains, with spreadsheets, manual checks, and a dash of prayer, just doesn’t cut it anymore. Today, companies are turning to Artificial Intelligence to turn their supply chains into smart, predictive, and almost self-healing systems.

If you’ve ever wondered how your online order arrives faster than your paycheck, or how big companies juggle millions of moving parts globally, the answer is: AI has entered the chat, and it’s transforming the entire game.

Table of Contents

Why This Matters Now

Global supply chains are more complex, and fragile, than ever. From geopolitical instability to climate change, unpredictable demand, and rising customer expectations, businesses are under pressure to deliver faster, cheaper, and greener.

Key challenges today include:

- Inventory overstock or shortages

- Inaccurate demand forecasting

- Disconnected systems and data silos

- Unpredictable shipping delays

- Sustainability pressure

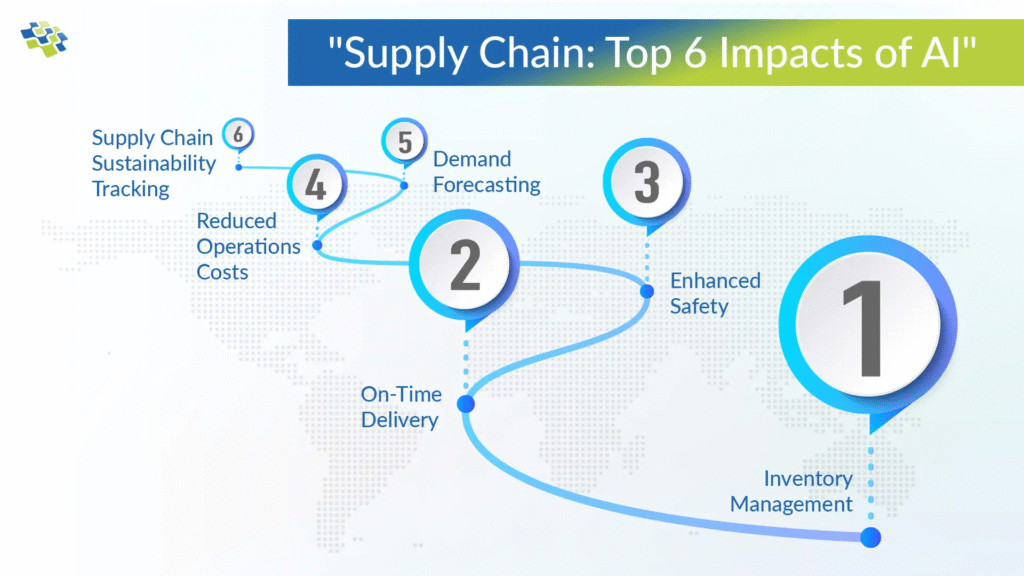

AI is emerging not just as a tool, but as a strategic necessity for optimizing these systems. It provides:

- Real-time visibility

- Predictive analytics

- Automation of manual tasks

- Intelligent decision-making

Let’s unpack how AI is making supply chains smarter, faster, and future-proof.

1. Demand Forecasting: AI Reads the Crystal Ball (Better Than Humans)

Guessing future demand based on past sales is like trying to drive forward by staring in the rearview mirror. It’s risky. And in today’s volatile market, outdated forecasting methods can lead to massive losses.

AI uses predictive analytics and machine learning to analyze:

- Historical sales data

- Market trends

- Weather patterns

- Social media sentiment

- Economic indicators

Result?

Accurate demand forecasts, not just monthly or weekly, but down to product, location, and time of day.

Real-world example:

Walmart uses AI to anticipate customer demand at individual stores, improving stock levels and reducing waste.

2. Inventory Optimization: Not Too Much, Not Too Little, Just Right

Too much stock? You’re losing money on storage.

Too little stock? You’re losing customers.

This is where AI finds the Goldilocks zone.

How AI helps:

- Tracks real-time inventory across warehouses and stores

- Predicts restocking needs based on live data

- Recommends transfers between locations to balance stock

With AI, businesses can:

- Minimize stockouts

- Reduce carrying costs

- Improve warehouse efficiency

Bonus: Smart shelves and IoT sensors can alert AI systems when items are running low or misplaced.

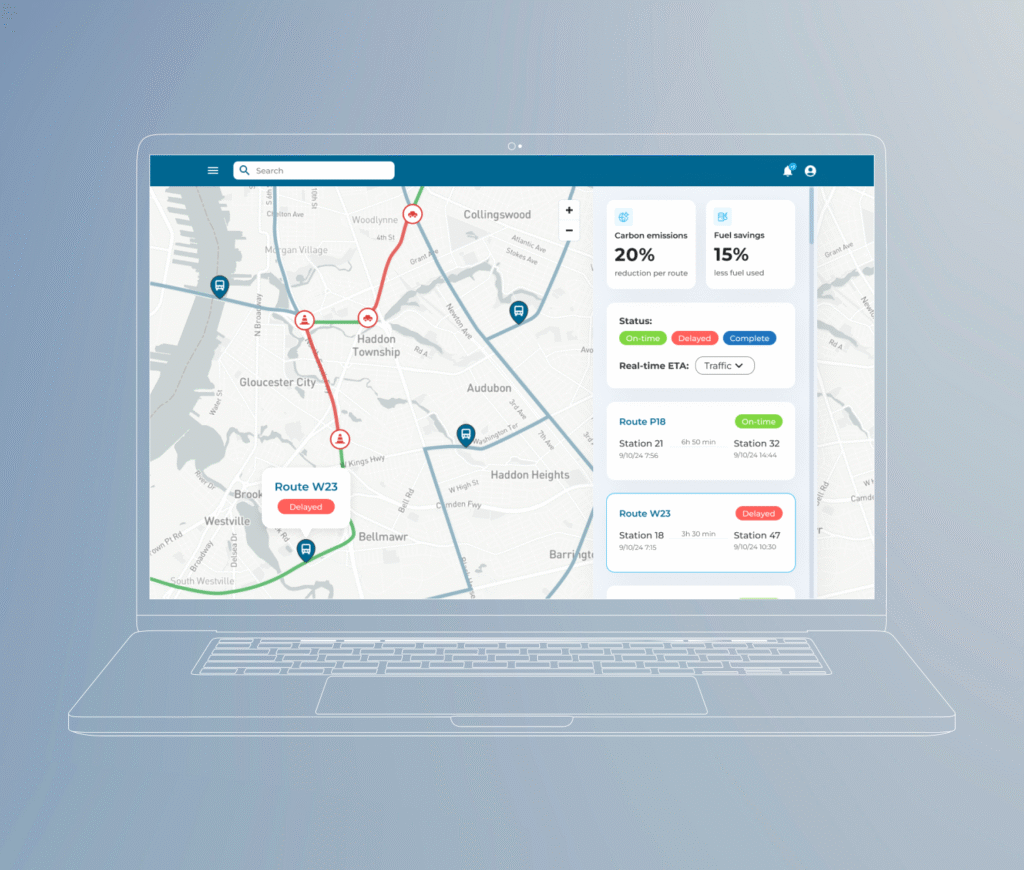

3. Route Optimization and Logistics: AI as Your Delivery Traffic Cop

Whether it’s raw materials coming in or finished goods going out, timing is everything in supply chains.

AI enhances logistics by:

- Analyzing traffic, weather, customs data, and driver availability

- Calculating the fastest, cheapest, and most fuel-efficient routes

- Predicting delivery delays before they happen

Example:

DHL uses AI-powered logistics platforms to reroute deliveries in real time, reducing delays and saving millions in fuel.

Even cooler?

AI can assign drivers, load vehicles smartly, and reschedule delivery windows, automatically.

4. Supplier Risk Management: No More Surprises (Hopefully)

In global supply chains, a single supplier hiccup can create a domino effect. AI can reduce the risk.

How?

- Continuously monitors supplier performance

- Analyzes political news, environmental data, and even social media for red flags

- Scores supplier reliability and risk in real-time

Result:

Proactive risk mitigation, like diversifying vendors, rerouting shipments, or pre-ordering from secondary sources.

Think of it as an AI-powered sixth sense, one that sees disruption coming before it knocks on your warehouse door.

5. Warehouse Automation: Robots + AI = A Logistics Symphony

Modern warehouses are no longer just shelves and forklifts. They’re data-driven hubs powered by AI.

Inside an AI-optimized warehouse:

- Autonomous robots pick, pack, and sort items based on real-time demand

- AI systems coordinate storage layout for maximum space efficiency

- Sensors detect temperature, humidity, or anomalies in inventory

Amazon’s secret sauce?

AI-driven robotics that reduce human travel time and increase order accuracy to nearly 100%.

It’s not about replacing humans, it’s about augmenting their speed and accuracy.

6. Real-Time Visibility: The End of “Where Is My Order?”

Customers and executives alike want one thing: visibility.

AI platforms provide a bird’s eye view of the entire supply chain by:

- Aggregating data from shipping companies, customs, GPS, and ERP systems

- Creating a real-time dashboard showing every shipment, order, and bottleneck

Bonus:

AI doesn’t just show where things are, it tells you why there’s a delay and what to do about it.

No more vague answers like “it’s stuck in transit.” AI brings clarity, fast.

7. Sustainability & Carbon Tracking: Greener, Smarter Chains

Sustainability is no longer a nice-to-have. It’s a business imperative, and AI can help track and reduce environmental impact.

AI enables:

- Carbon footprint analysis for every step of the supply chain

- Route optimization to reduce fuel consumption

- Smart packaging decisions to cut waste

- Supplier scoring based on green credentials

Example:

Unilever uses AI to monitor its supply chain emissions and improve eco-efficiency across its global operations.

Supply chains that save money AND the planet? Yes, please.

8. Chatbots & Virtual Assistants for Supply Teams

Communication bottlenecks can slow down even the best supply chains. AI-powered virtual assistants now:

- Track shipments

- Answer order status inquiries

- Schedule deliveries

- Send automatic alerts to vendors and teams

These bots are multilingual, tireless, and way faster than email chains. Perfect for managing the daily flood of queries without overwhelming your staff.

9. Crisis Management & Scenario Simulation: Your AI Emergency Playbook

What if a port shuts down? What if a truck breaks down? What if a supplier vanishes overnight?

AI can simulate what-if scenarios, analyze thousands of variables, and suggest the best course of action, in real time.

Example:

During the pandemic, some companies used AI to simulate lockdown scenarios and shifted sourcing in hours, not weeks.

Crisis is inevitable. But with AI, panic doesn’t have to be.

FAQ

Q1: Is AI too complex for small and medium-sized supply chains?

A1: Not at all. Many AI tools today are modular and cloud-based, allowing SMEs to scale gradually based on need and budget.

Q2: Will AI replace human jobs in supply chains?

A2: Some repetitive tasks will be automated, but AI also creates new roles, from AI analysts to robotic maintenance technicians. The future is collaborative, not robotic.

Q3: What are the biggest risks of using AI in supply chains?

A3: Overreliance, poor data quality, and lack of transparency. That’s why AI should always be supervised, with ethical frameworks in place.

Final Thoughts

The supply chains of the past were complex. The supply chains of today are chaotic. But the supply chains of the future? Smarter, faster, more resilient, thanks to AI.

From predicting demand to automating warehouses, routing trucks, and even saving the planet, AI isn’t just optimizing supply chains, it’s rebuilding them for a better, more connected world.

So next time your online order arrives ahead of schedule or your favorite store never runs out of stock, remember: there’s a little AI magic behind the scenes.

Want to explore more AI-powered business breakthroughs? Stick around at aihunterguides.com, where tech meets impact, and we make it all make sense (without putting you to sleep).

Pingback: Amazon Humanoid Robots: Amazon’s Bold Move